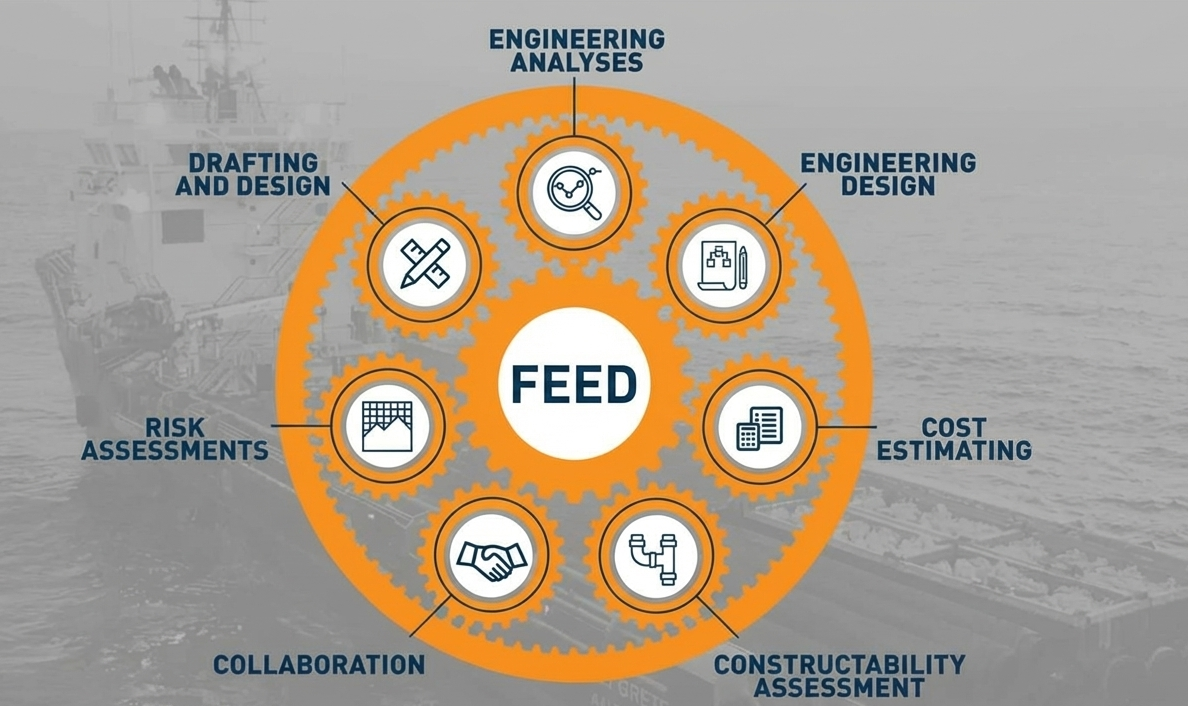

At Selva, every project begins with a strong foundation that is executed successfully. Our project conceptualization process transforms ideas into executable strategies by bringing innovation, industry expertise, global standards and structured planning.

We are committed to transform the visions into reality by harmonizing the innovation with practicality, maintaining a strong focus on excellence and creativity.

.png)

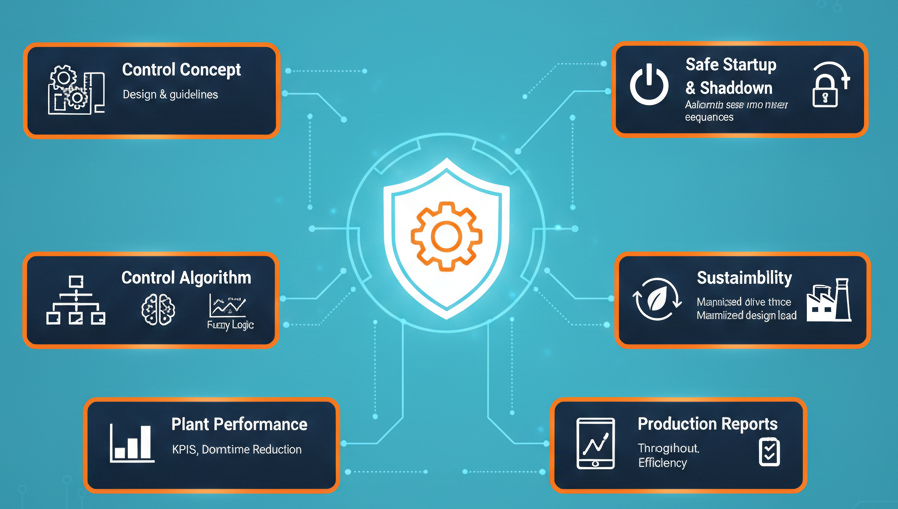

At Selva, we design the complex industrial needs into tailored automation solution with standard and efficient architecture.

At Selva, our control solutions focus on the core principle of industrial automation—designing and implementing the precise control that governs safe, efficient, and reliable plant operations.

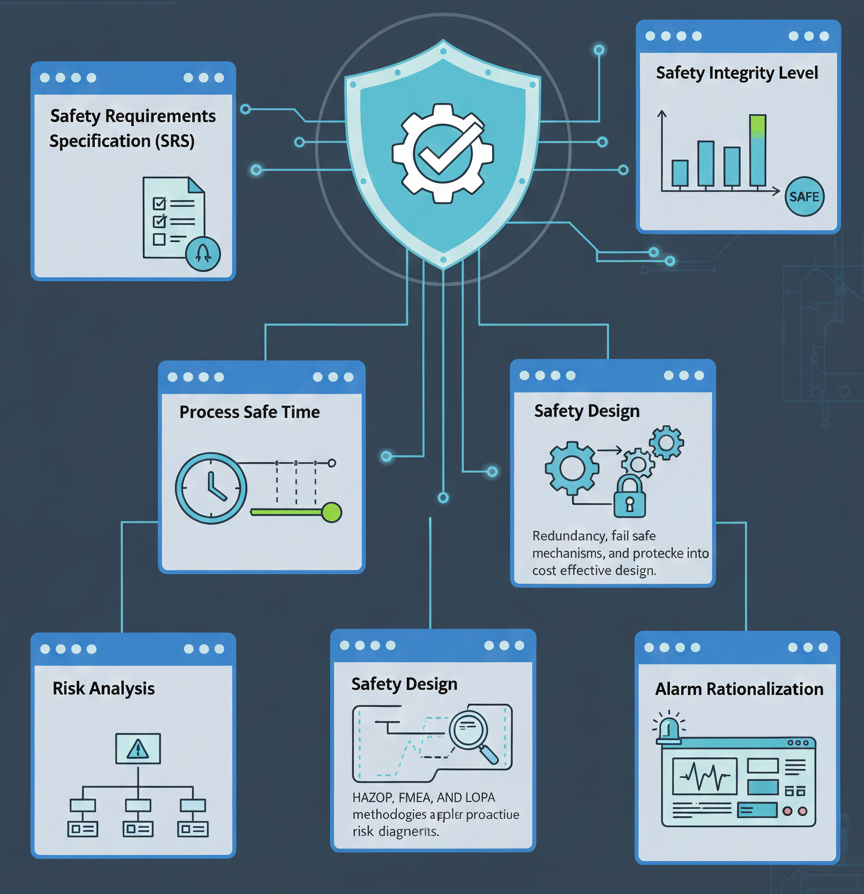

In SELVA groups, safety is embedded into every stage of our engineering and automation solutions. We ensure that all systems meet the highest standards of functional safety, reliability, and compliance.

Safety is not an afterthought—it is the nucleus of safe engineering practice.

At Selva, we recognize that modern automation systems demand more than performance — they require robust security.

We deliver OT security solutions that are robust, scalable, and future ready.